Link’s family of LB20 ramps are now 25 pounds lighter, feature pull-style, gas-spring-assist lifting mechanisms, stow at an 8-inch vertical depth, ship fully assembled and are even easier to install than previous models.

SIOUX CENTER, Iowa, (Feb. 22, 2024)— Link Mfg., Ltd., the leading U.S. manufacturer of lightweight folding aluminum ramps, announced the introduction of its newly redesigned LB20 family of ramps today. One of nine models of the LB20 will be on display to the industry for the first time during NTEA Work Truck Week 2024, March 5–8, 2024, in Link’s booth #4619.

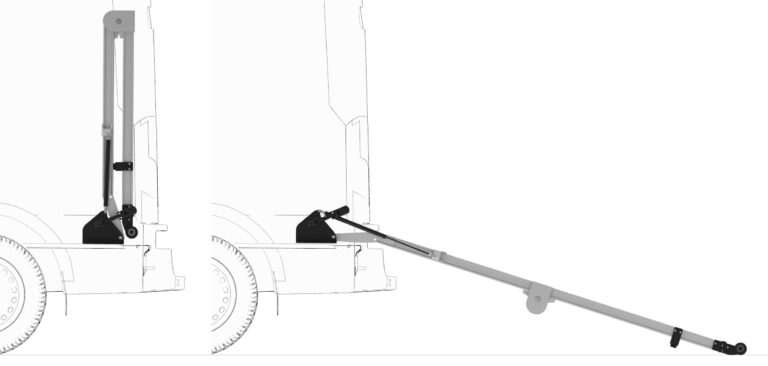

Link’s family of LB20 ramps has been reengineered to significantly improve installation time, operational functionality and the end-user experience. Seven of the nine ramps now each feature two pull-style, gas-spring-assist lifting mechanisms. The gas-spring devices are lighter weight, leading primarily to the ramps’ 25-pound weight savings and providing greater lift assistance, meaning less exertion and lifting force required by users.

“With their new gas-spring-assist feature, Link’s LB20 ramps are now even easier to deploy and stow, making them ideal for vehicles that use their ramps with greater frequency,” said Lynn Blake, senior account manager for Link Mfg. “And with older individuals and females making up an ever-increasing percentage of the workforce, the reduced lifting effort and increased ease of use will be greatly appreciated.”

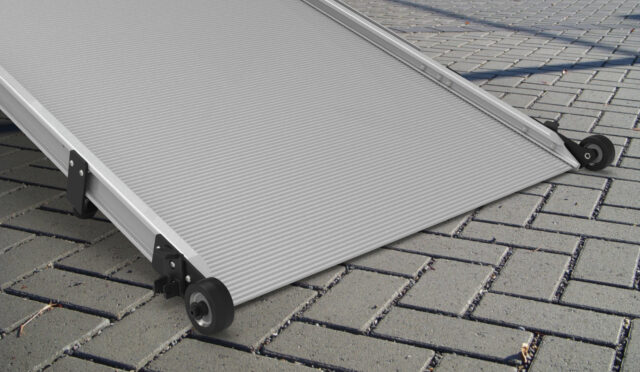

Fitted with their slimmer gas springs, the reengineered LB20s provide significantly greater clearance and less interference with steps and with both standard and extended bumpers. The ramps now feature a lower-profile transition threshold at their top, making it easier and smoother for dollies and other wheeled equipment to enter and exit the vehicle. When stowed, the ramps have a narrow, less than 8-inch silhouette, providing 34 percent more valuable room in the cargo area.

“When in their upright, vertical folded position, the redesigned ramps now take up less than 8 inches of horizontal space just inside the door,” Blake said. “Now our ramps can be mounted even closer to the doors and can be quickly accessed, opened and then closed again and out of the way in seconds. And unlike hydraulic liftgates and small electric cranes, Link ramps require no training to operate, enabling workers to start using them immediately after installation.”

The LB20’s new base plate has also been reduced to 11 inches in depth and now features a larger mounting pattern to accommodate more mounting holes and fastener sizes, making installation even easier for upfitters. Link LB20 ramps will now have consolidated part numbers and will ship fully assembled with attached base plate, wheels and gas springs on the applicable seven models. Customers will continue to experience the industry-best lead times with fully assembled LB20 ramp units. Link is also happy to drop ship ramps on a just-in-time basis through a Link-certified dealer.

Link ramps are designed to meet a wide variety of uses, with dimensions ranging from 24 to 47 inches in width, comfortably accommodating standard hand trucks and other cargo conveyance and wheeled equipment. Link’s bifold ramp lengths vary from 72 to 135 inches, and extended LT30 ramp models reach 119 inches and feature adjustable support mechanisms for added stability.

A 42-inch by 108-inch version of the LB20 ramp is also available, catering to an array of applications. The 42-inch-wide ramp is perfect for fleets and vehicles serving the last-mile delivery segment that don’t have to deploy ramps at every stop, because it leaves enough room for door entrance and egress without being unfolded.

Seven of the nine LB20 models will be available with the spring-assist feature, and the two smaller and lighter of the nine ramps will come without it. All models will now also come with Link’s wheel kit as a standard feature, which will allow the ramps to deploy and retract on a wide variety of surface angles and materials more smoothly.

LB20 ramps are and have always been designed for reliability and durability, using extruded high-strength aluminum. The extensive line of nine LB20 sizes provides an option for virtually any application.

“Link ramps are designed to be so robust, our upfitter customers tell us that they often outlast more than one vehicle,” said Blake. “Whereas liftgates and cranes can drain vehicle batteries, they also require significantly more maintenance and cost between two and four times more to purchase and install than a ramp, making ramps far more practical.”

Link LB20 ramps will be commercially available in the second quarter of 2024. The new ramps will ship in the form of a fully assembled unit. The LB20 ramp can be ordered through Link’s nationwide network of ramp dealers. For more information on Link ramps or to find a dealer, please call (800) 222-6283 or visit https://www.linkmfg.com/dealer.

About Link Mfg., Ltd.

Link develops and manufactures a variety of suspensions, suspension controls and specialty air management products, engineered to address the unique needs of commercial vehicle, trailer, motorcoach, transit bus, shuttle bus, recreational vehicle and specialty vehicle markets. Link is the worldwide leader in heavy-duty truck cab air suspensions marketed under the brand name Cabmate. The company is also a leading innovator in vehicle air management and dynamic air suspension control technologies marketed under the brand names SmartValve, Smart Air Management Systems (SAMS), and Road Optimized Innovations (ROI). With manufacturing locations in the United States and Canada and distribution in Europe, Link Mfg., Ltd., is an IATF 16949– and ISO 14001: 2015 (EMS)–certified company whose primary products include cab, auxiliary and chassis suspensions, including heavy vocational, off-highway and air suspension management technologies. Link also manufactures specialty products such as Cat’s Eye–brand tire pressure monitoring and equalization systems, ramps and other products designed to enhance the productivity of commercial vehicles.

Link is a registered trademark of Link Mfg., Ltd.