Collaborative Engineering & Design

Our collaborative engineering approach allows OEM engineering departments to extend their design, engineering and testing capacity to make their products better—more distinctive with higher profitability. In choosing Link Manufacturing, OEMs benefit by having access to the latest engineering applications and extensive design and test capabilities.

Link brings years of experience tailoring solutions to meet the rigorous demands of today’s various markets. Link’s collaborative engineering approach delivers performance for several parts of the trucking industry; enhancing installation efficiency; leading the industry in capacity range; and improving overall driver well-being. We are able to drive down overall cost and extend OEM resources while providing the stability you need and the ride you want.

Applied Technologies Center

To encourage product innovation, our 10,000 sq. ft. Applied Technologies Center (ATC) facilitates development of new products and the analysis of emerging engineering technology to apply to future OEM products. The ATC is dedicated to the durability and performance testing of all Link Manufacturing products.

NVH Analysis

Our Noise, Vibration and Harshness (NVH) analysis leverages accelerometer and sound pressure level data acquisition to evaluate and compare the noise levels, vibration and roughness of any given ride. This is essential to ensure your overall product performs better.

Vibration Testing

Vibration Testing is performed with Link’s in-house simulators. Our engineers are able to quickly evaluate vibration isolation performance & durability. These results guide engineering and design modifications to provide exceptional product performance.

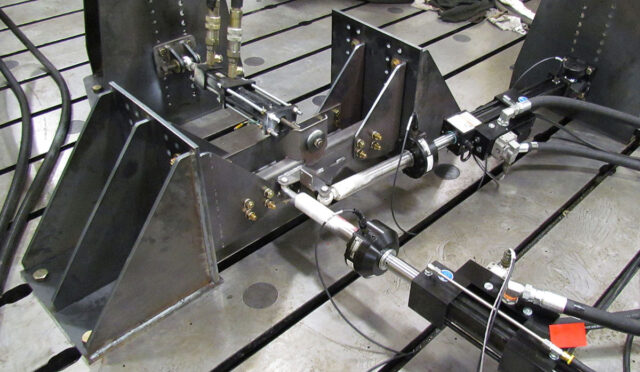

Durability Testing

Durability Testing & Analysis ensures performance standards and OEM specifications are met. Our Multi-Axis Servo-Hydraulic actuators & controllers are capable of testing complete suspension systems or individual components and to anticipate and solve durability issues before problems arise.

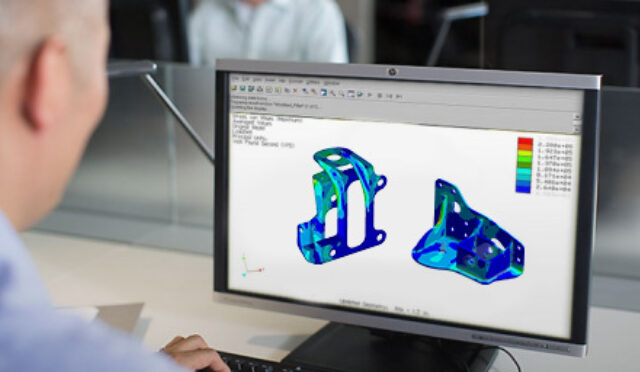

Virtual Design & Simulation Testing

Our virtual design and simulation testing minimizes prototype iterations and provides feedback earlier in the OEM design process. This is used for fatigue and vibration analysis; finite element analysis; kinematics and compliance; rigid body dynamic analysis; and multi-domain simulation.

Ride, Handling & Strain Evaluation

Ride, Handling and Strain Evaluation combines NVH Analysis with on-track, on-road and in-lab testing to evaluate ride and handling performance. Our in-lab testing utilizes a 7-Axis Servo-Hydraulic Cab Ride Simulator.