Vocational Truck Suspensions 101

How to maximize control, stability, and comfort by choosing the right heavy-duty vocational truck suspension technology.

Vocational trucks are integral to the transport and logistics industries. Their suspension systems, pivotal for performance, safety, and comfort, have seen significant evolution. The most important role of any suspension is to provide positive control of an axle’s position and movement and the requisite roll stability. However, a suspension is also necessary for supporting the vertical load and isolating the occupants and equipment from road inputs. It’s important to understand all aspects of the inner workings of a vocational truck suspension, how those parts affect the vehicle and driver, as well as how to specify your vehicle’s next suspension for its desired application.

An Endemic Problem

In today’s vocational equipment domain, suspension geometry and spring type are the two biggest influences on driver comfort and equipment protection. Both factors should be considered, along with service environment, duty cycles, and other critical details when specifying a suspension for a vocational truck.

Too often OEMs and body builders alike apply a one-size-fits-all approach to vehicles with a different gross vehicle weight (GVW), center of gravity (CG), and body configuration. While a mechanical walking beam suspension may satisfy the needs of a high GVW dump truck of 96,000 pounds, it will deliver a much harsher ride and limited equipment protection on a lower GVW application, such as a 66,000-pound utility truck. It may also limit body roll to the point where it will not provide the driver with enough feedback to know the vehicle is nearing a tipping point.

Air vs. Mechanical Spring Suspensions

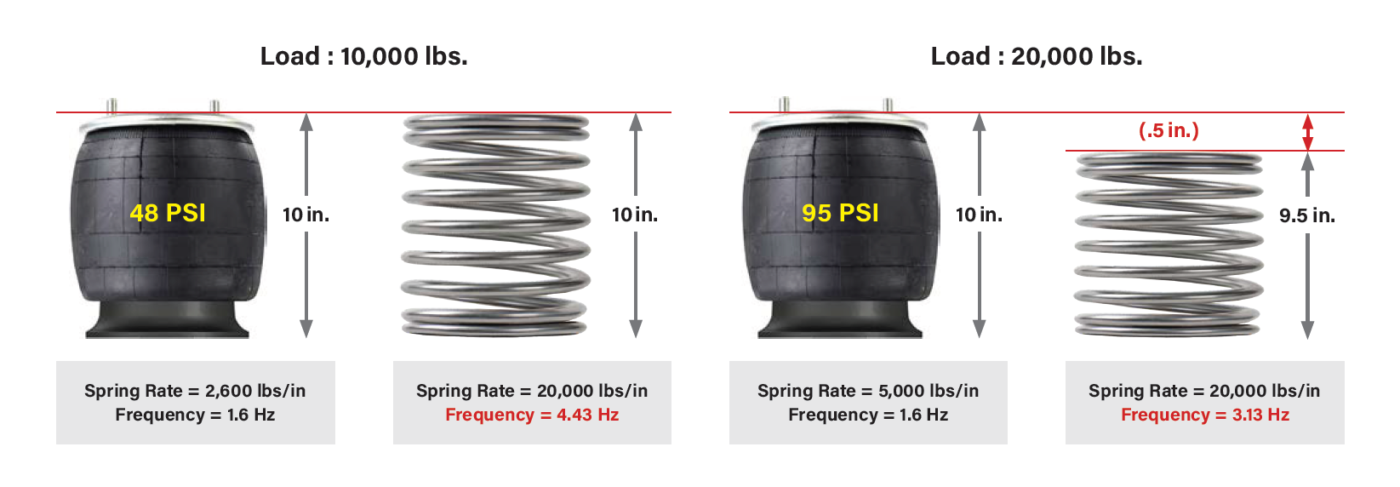

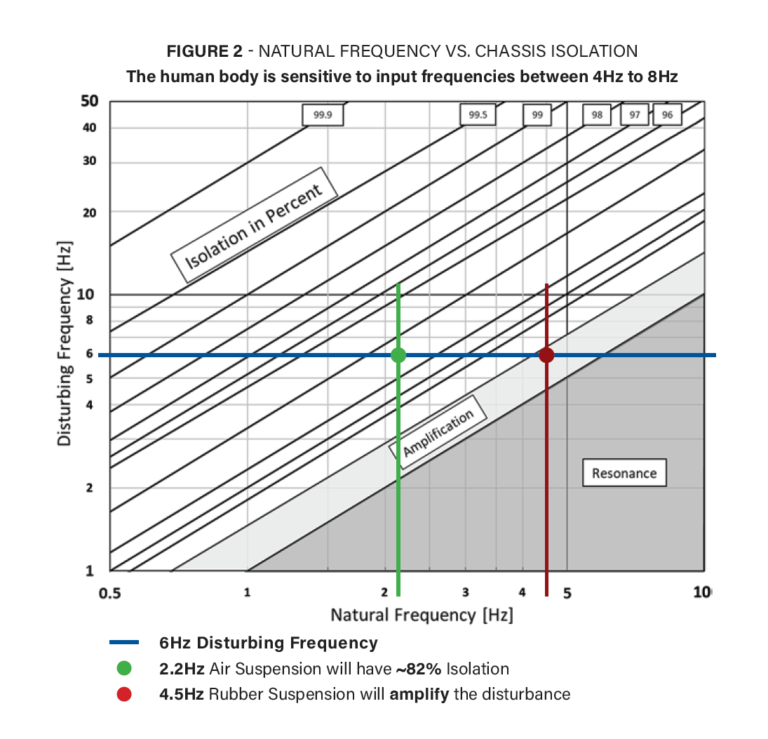

Most mechanical spring and rubber-ride suspensions have an indirect correlation between roll stability and ride quality. While these suspensions offer more roll stability generally, when used in tandem configurations, they offer worse ride comfort and reduced equipment protection. In contrast, typical air suspensions can decouple the link between roll stability and ride quality, giving the suspension the ability to provide ample roll stability and notable ride quality. However, when translated to tandem drive suspensions, there can be another indirect correlation between roll stability and traction.

Most air suspensions will have reduced traction, even while providing the necessary roll stability for a higher-center-of-gravity vehicle, such as a cement mixer. When driving in an off-highway environment, if the tires of a truck on one side are climbing a mound, the mechanism providing roll stability will force the other side to rise, causing the truck to lose traction.

Recently, the industry has been trending toward using an increasing number of rubber block walking beams and air spring suspensions. This increase in the use of rubber block walking beams vs. spring walking beams has more to do with weight reduction than comfort improvement. The unfortunate reality for drivers is that many rubber block walking beams nearly become a solid-mount state when fully loaded or in the vehicle’s creep mode to protect the suspension’s rubber from being overstressed and breaking down. Inevitably, as the rubber ages and begins to lose its elastomeric properties, the suspension’s already poor ride quality will diminish. Therefore, it’s important to consider the truck’s lifecycle when considering which type of suspension to specify, as well as many other application specific factors.

Application-Specific Insights

Specifying the appropriate suspension is not a “one-size-fits-all” endeavor. It requires a thorough understanding of the vehicle’s operational landscape.

Operational Environment

Urban environments, characterized by smooth roads, might not demand the robustness required by off-road or construction scenarios. In urban settings, the emphasis might be on ride comfort and reducing wear and tear, thus favoring air ride suspensions. However, in rugged terrains, the stability and traction of walking beam systems might be more appropriate.

Load Type

A truck transporting delicate equipment might prioritize the air ride’s ride quality to ensure the safety of its cargo. In contrast, a logging truck might focus on traction and stability, considering the uneven and potentially slippery terrains.

Frequency of Load Changes

Trucks with frequent load changes, such as delivery vehicles, benefit immensely from air ride suspensions due to their adaptability. The system's ability to adjust to varying loads in real time ensures the truck remains balanced and will continue to isolate road inputs in the same manner so drivers will experience consistent vehicle handling and response.

Budgetary Considerations

While modern suspension systems offer numerous advantages, they come at a cost. Initial investments for advanced systems like air ride suspensions might be higher, but they could lead to long-term savings in maintenance and operational costs. Conversely, traditional systems might have a lower upfront cost but might require more frequent maintenance or replacements. By aligning suspension technology with the operational needs, fleets can achieve optimum performance, safety, and economic efficiency.

Specifying the Right Suspension: Balancing Effectiveness, Stability, Control, & Comfort

There is no easy solution that addresses all environments and all concerns. While the severe-duty segment of the Class 8 vehicle universe is small, it is also the most diverse regarding application, body style, number of axles, ride heights, center of gravity, and addition of auxiliary axles like pushers, tags, stingers, etc.

There are several factors for fleets and owner-operators to seriously consider during the process of suspension specification for their next vehicle specifications:

100% Off-Highway Use (Medium to Low Center of Gravity)

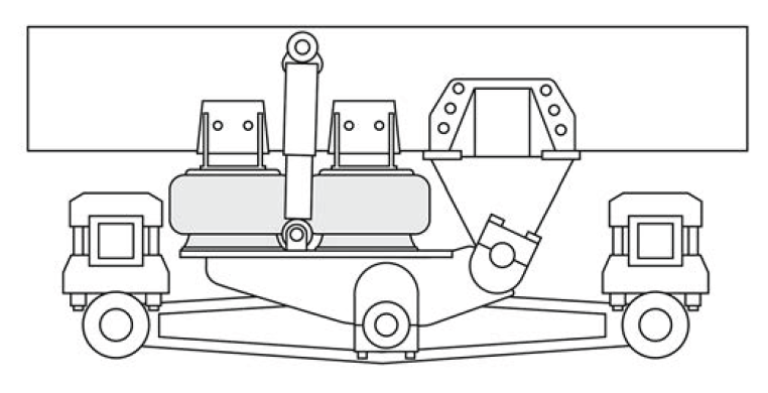

If your vehicle is spending the majority of time off highway or on poorly maintained, temporary worksite roads with lots of articulation events, you should be using a walking beam suspension that will offer the best chance of keeping all tires in tractive contact with the ground. If your application has a medium to low center of gravity and zero to two auxiliary suspensions, then an air-over-walking-beam suspension is recommended for the best driver comfort and equipment protection.

100% Off-Highway Use (High Center of Gravity)

Similar to above, if your application is spending the majority of time off-highway or on poorly maintained, temporary job site roads with lots of articulation events, you should be using a walking beam suspension that will offer the best chance of keeping all tires tractive and in contact with the ground. If your application has a high center of gravity and more than two auxiliary suspensions, then a spring/rubber type walking beam is recommended, but keep in mind that the driver is in for a rough ride.

25% Off-Highway Use

This is the same as above, but many fleets choose to use a rubber ride walking beam suspension, even though much of the time the vehicle stays on maintained roads. In this instance, an air-over-walking-beam suspension would likely be a better choice for driver comfort, particularly for lower center of gravity applications with limited auxiliary suspensions.

Truck Load During Use

If your return trips are empty or if your load is being depleted as you travel, you should be using an air suspension that can adjust the air spring pressure to keep your ride quality, driver comfort, and ride height consistent.

The uniform ride height is important to reduce driveline vibration, which is vital to improving the life of the driveline while also helping to reduce vibration inputs felt by the driver.

Walking on Air

Almost every truck runs empty for up to half of its life. This is especially true for vocational trucks such as dump trucks and cement mixers.

Link Manufacturing’s Air Link® air-over-walking-beam technology was patented close to 30 years ago and was originally designed to cope with extreme payloads and the rigors of harsh off-highway defense applications. Vastly superior to heavy-duty leaf spring, rubber block walking beam, two-spring “six-rod” and trailing arm suspensions, the Air Link suspension provides a smooth, comfortable, uncompromising ride.

One of the real benefits of the Air Link suspension is that the ride quality is virtually unchanged when running empty, saving the driver and truck from the pounding associated with steel springs or rubber block suspensions that become too stiff when empty to isolate the driver and equipment from road inputs.

The Air Link is available in capacities ranging from 46,000 to 85,000 pounds and has been adopted for use in many severe-duty applications. The main reason fleets try the Air Link for the first time is to promote driver comfort and retention as well as equipment protection. Another advantage to the fleet is the potential for more trips to occur in the same shift, because drivers can safely operate unladen vehicles at higher speeds and on rough terrain during return trips, due to the Air Link’s superior ride characteristics.

Concluding Thoughts on Specifying the Right Suspension

For fleet managers and decision-makers, it’s important to conduct comprehensive research, understand your specific vehicle needs, and align them with the right suspension system. As with all technological integrations, there’s a learning curve, but the potential benefits in terms of performance, safety, and cost-efficiency make the journey worthwhile.

Air Link offers the best combination of ride quality, roll stability and traction for most applications. The air-over-walking beam suspension is designed and engineered to maximize driver control and comfort while reducing equipment damage. If you have questions regarding the Air Link and how it can benefit your fleet, contact us today.

Blog Author

Mark Molitor

Senior Product Manager - Chassis Suspensions