The Benefits of a Semi-Active Cab Suspension

Understanding Traditional Cab Air-Ride Suspensions & Their Limitations

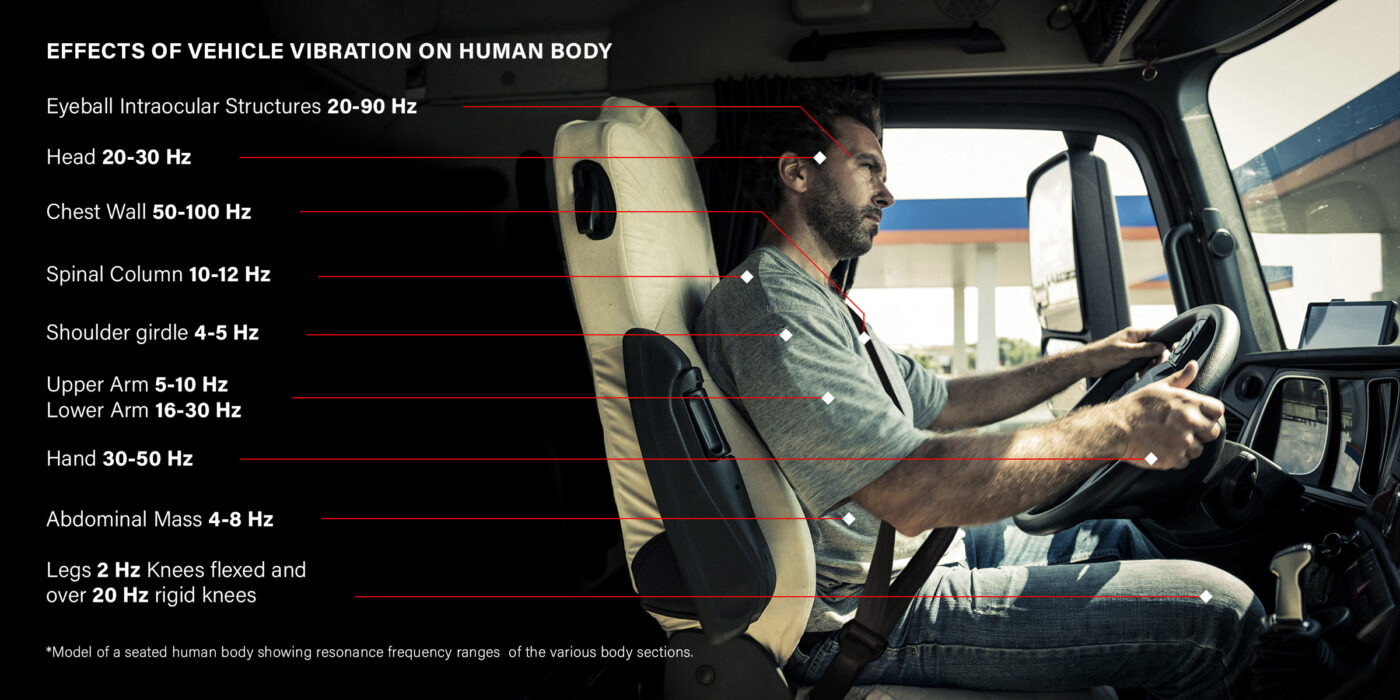

A truck’s cab suspension has the primary function of isolating the cab from the truck chassis’ vibrational forces, resulting from impacts like a large bump or pothole or small events like tire vibrations at highway speeds. Typically, the cab suspension’s function is looked at for the sole purpose of driver-comfort, but the function of a cab suspension is about safety. Safety breaks into two sub-categories, driver comfort and cab stability.

The suspension isolates the cab from the chassis to reduce the impact and vibrational forces felt by the driver. Reducing whole-body vibration and improving stability over a full day of driving has a dramatic impact on reducing fatigue and drowsiness for operators. The suspension also keeps the cab environment stable so the driver can maintain line-of-sight with the road and steady contact with vehicle controls. Both functions ultimately equate to safety because a truck is a work environment and not a passenger car.

Traditional, or passive, cab suspensions are designed to find the best compromise between stability and comfort. Air Spring(s) are used to carry the load of the cab, reducing the impact transferred to the cab by compressing the air inside, and the shock absorber(s) are tuned to compromise between comfort and stability but have a fixed response based on the velocity of the suspension. For comparison, consider the differences between the soft ride of a luxury car to the stability of a sports car.

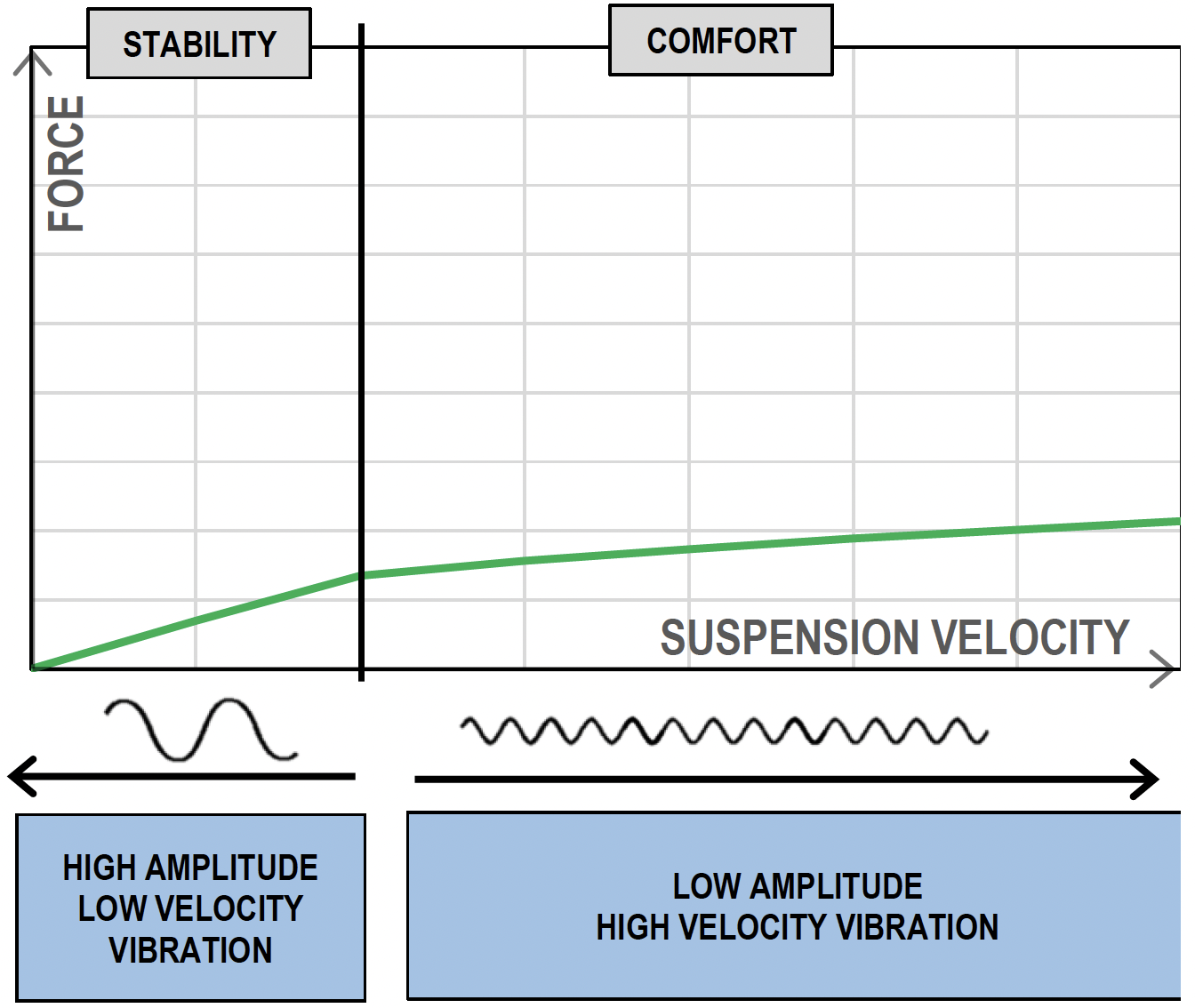

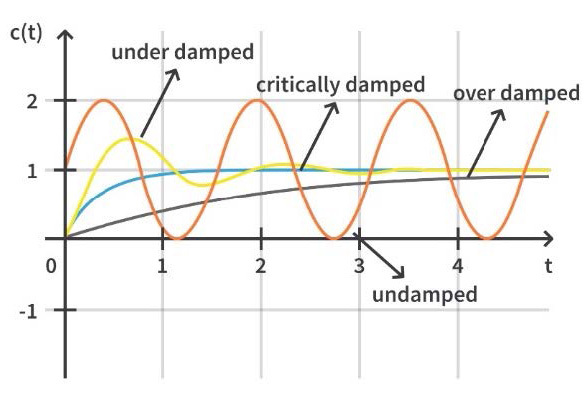

A soft suspension, shown above, performs well for comfort, but performs poorly for stability.

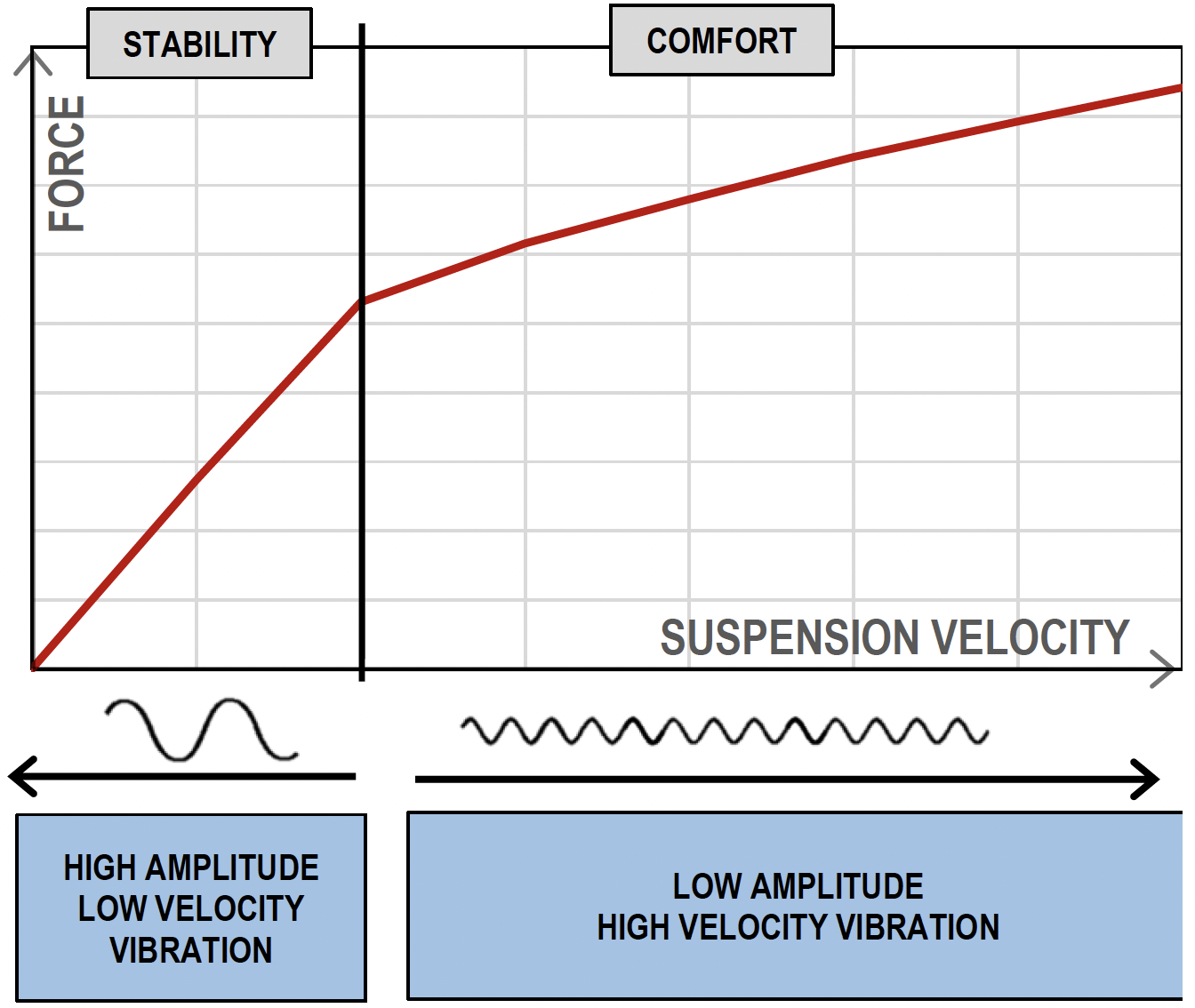

A stiff suspension, shown above, performs well for cornering and stability, but performs poorly for comfort.

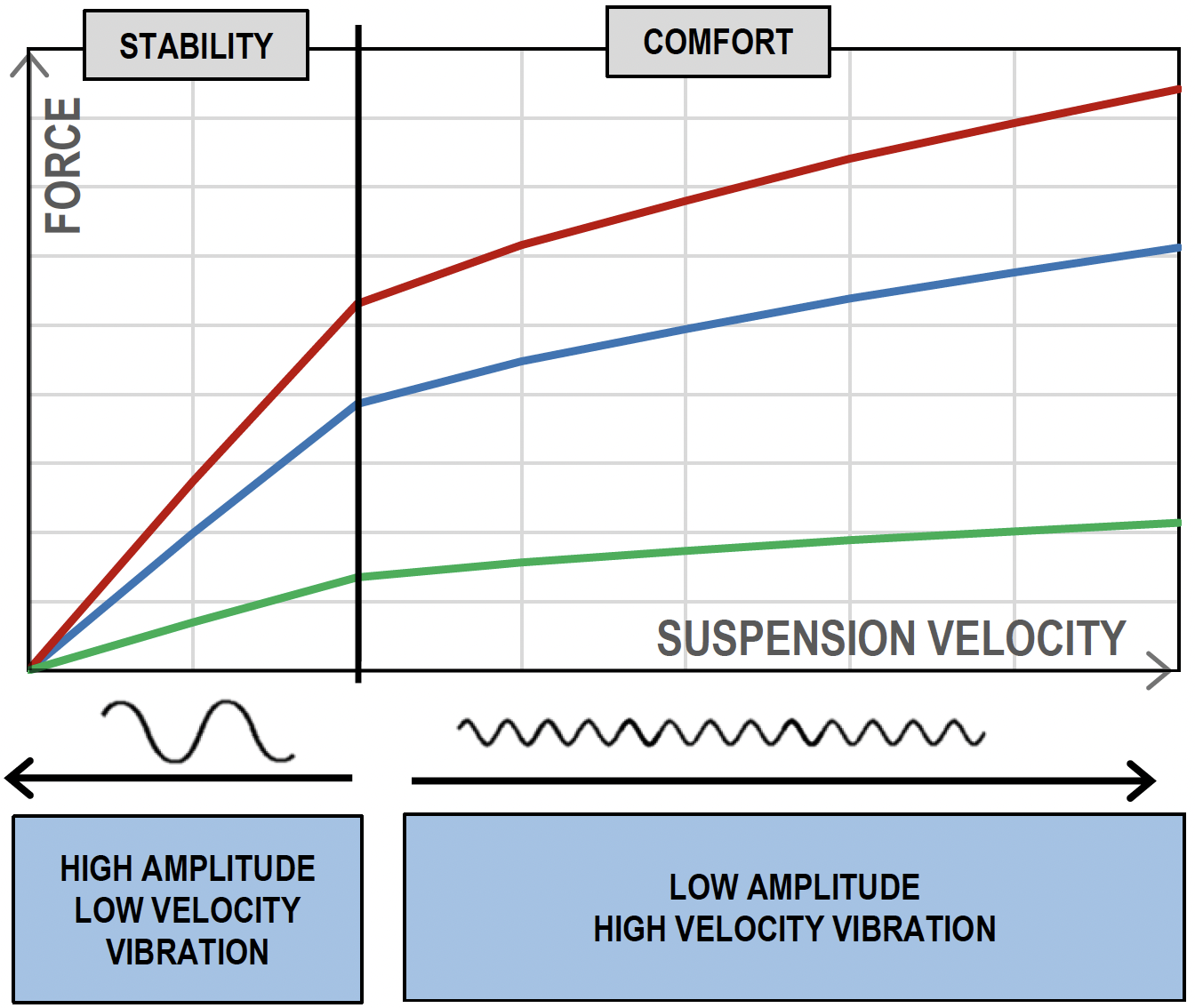

The blue curve shown above displays the standard damper performance compromise. The compromise is unavoidable in a passive system because a damper needs to be tuned to remain stable at maximum cab load.

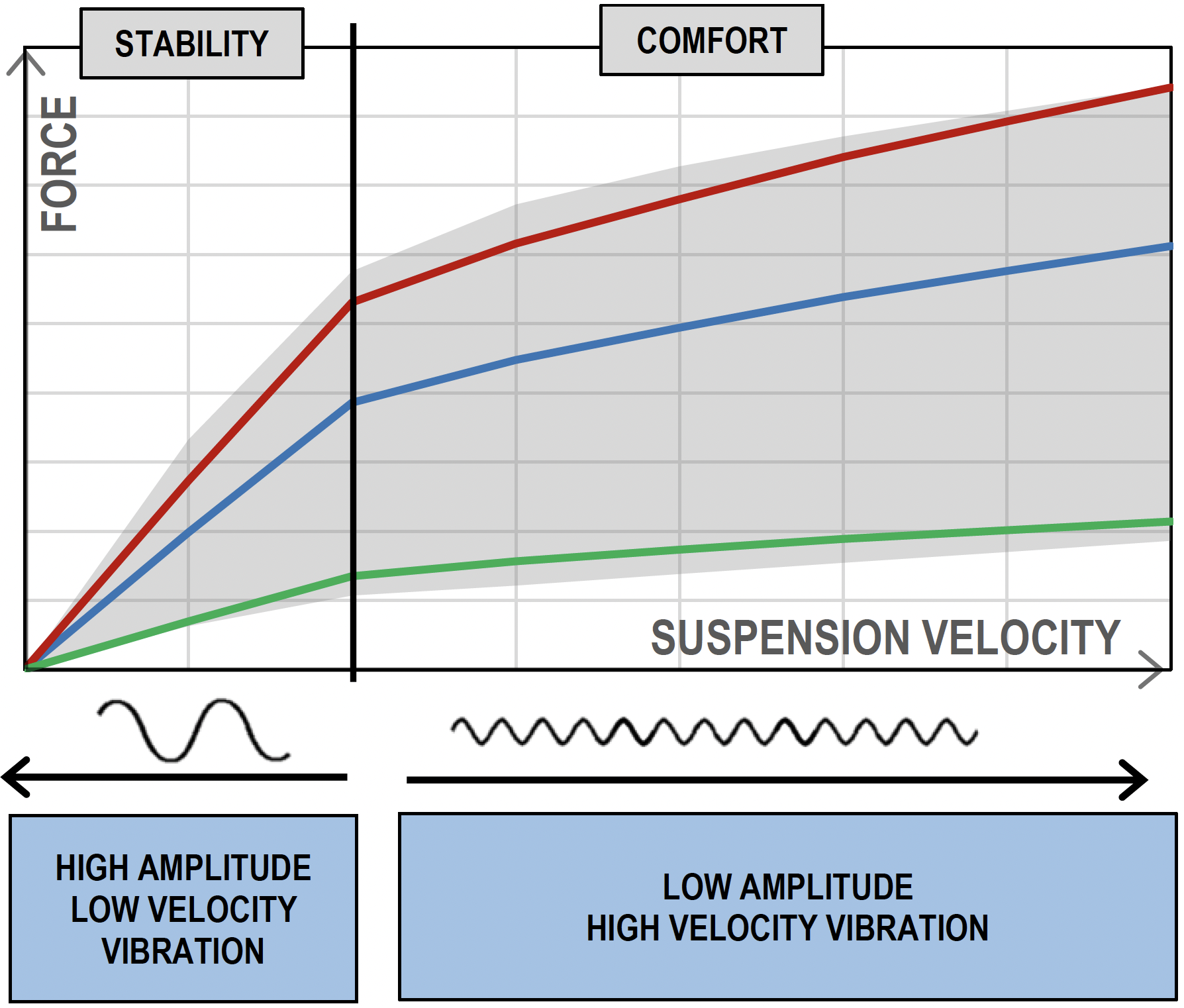

As shown in the shaded area, a semi-active suspension's versatility lies in its ability to capture a wide range of force reactions at all velocities, both in rebound and compression. This means it can provide the best attributes of a stiff and soft damper at any moment.

Semi-active systems optimize for both stability and comfort without compromise. A semi-active system provides a continuously variable damping rate that can be adjusted in real time using a control algorithm. The semi-active system offers dramatic ride improvements while still being a cost-effective option, making it ideal for the commercial trucking industry.

Link’s ROI Cabmate Provides an Advanced Yet Practical Solution

In 2019, Link Mfg., introduced the ROI Cabmate semi-active cab suspension. The ROI Cabmate is constantly assessing environmental circumstances while responding simultaneously. Using Link’s proprietary algorithms, the system interprets the stream of information from all the system’s sensors in real time and responds by continuously adjusting the stiffness of the dampers to optimize ride stability and comfort.

The system operates at speeds beyond human perception, adjusting shock absorber stiffness with computer-controlled precision. The result is optimized ride comfort, improved cab stability and an overall reduction in noise and vibration.

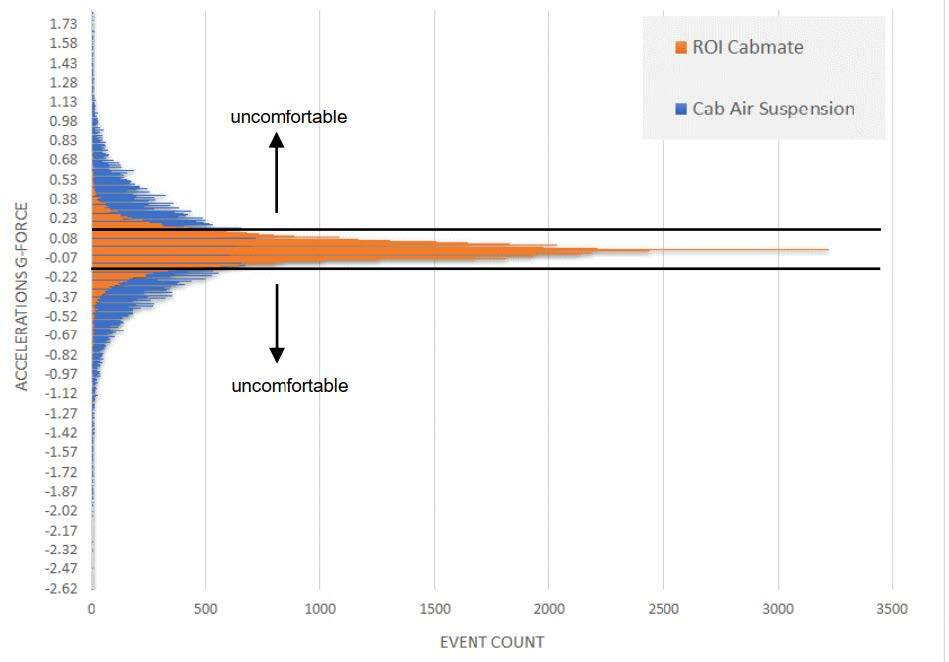

In a shake test from 0.5–20 Hz, Link’s ROI Cabmate semi-active cab suspension reduced longitudinal vibration above 0.15g by 76%.

Four versions of the same vibration are graphed above, using a bump in the road as an example. The orange line depicts a suspension with no damper at all; thus, the air spring keeps bouncing. The black line depicts an overdamped suspension, so it takes a long time to return to the neutral. The yellow line depicts a tuned damper that floats but has terrible body roll in cornering and would bottom out on a pothole. The blue line depicts ideal, critically damped (semi-active suspension), meaning it returns to its neutral position quickly, with no or minimal bounce.

Fleets will find numerous advantages associated with any vehicle fitted with Link’s ROI Cabmate semi-active cab suspension system, beginning with protection of the driver and the whole-cab asset. In addition to improving on-highway cab comfort, the ROI Cabmate can be a game-changing technology for off-highway applications. Reducing driver fatigue influenced by vehicle vibrations and enhancing ergonomics will most certainly enable operators to traverse an uneven route more quickly and safely, enabling productivity to rise and additional runs to be made in a single shift.

Benefit #1: Reduced Health Risks and Increased Productivity Through Improved Suspensions

According to the study published in the Journal of Safety Research, vibrations of 4-10 Hz were found to be most effective at inducing drowsiness. This frequency range can induce significant drowsiness within 30 minutes, necessitating research to identify ways to minimize whole-body vibration components that contribute to drowsiness.

Studies have shown the existence of a significant correlation between improved suspensions and reduced health risks. Link’s ROI Cabmate has been demonstrated to reduce vibration in the 4-10 Hz range by 18.2% vertically and 30.2% longitudinally. Because this range is also where the head, chest and abdomen vibrate easily, reducing the specific vibration range, the ROI Cabmate can lesson associated symptoms like drowsiness, lower back pain (LBP), spinal injury, sciatic nerve pain, general discomfort, and fatigue.

Benefit #2: Improving Driver Retention and Recruitment

Addressing driver recruitment and retention has become a critical concern for fleets. According to a study by the American Trucking Association’s (ATA’s), turnover rates for large fleets hover around 90%. This indicates most fleet hires last less than one year.

The expense to turn over a driver costs fleets over $8,000 on average, including training, recruiting, productivity loss, insurance, etc. A medium-sized fleet of 200 trucks could spend $1.6M annually in expenses related to keeping enough drivers in their fleet.

With comfort and safety being key factors for driver retention, a survey by the Commercial Carrier Journal (CCJ) revealed that 69% of drivers wanted special seats for improving comfort during long hours of driving. Here, a semi-active cab suspension like the ROI Cabmate can step in to address these issues, improving the ride at the source instead of only at the seat location.

Benefit #3: Capital Equipment Maintenance and Equipment Lifecycle Benefits

Semi-active suspensions may offer significant benefits over traditional suspensions when it comes to maintenance and the equipment lifecycle.

A shock absorber, for example, converts kinetic energy to heat energy to slow down the suspension bounce (damping). Over time, the repeated heat cycles degrade the oil’s viscosity, reducing performance and increasing heat generation until failure occurs. Replacing shock absorbers at planned intervals is standard practice among many commercial vehicle maintenance professionals.

Semi-active suspensions manage these heat cycles more efficiently, prolonging the shock absorber’s life. These suspensions can maintain their programmed performance even as the shock absorber begins to degrade, which makes them a viable and efficient choice for long-term use.

Benefit #4: The Benefits of Semi-Active Suspension Technology for Zero Emission Vehicles

The benefits of semi-active suspension technology extend to zero emissions vehicles (ZEVs) as well. Many of us have experienced the dramatically reduced background noise in the absence of an internal combustion engine while driving or being a passenger in a hybrid or fully electric passenger car. With a lower noise floor, other sources of noise and vibration become more noticeable. Therefore, the vibration reduction offered by a semi-active system becomes crucial for ZEVs.

Class 8 trucks utilize compressed air for various operations, traditionally supplied by an engine-driven compressor. However, this air consumption will directly impact miles per kWh in ZEVs. Link’s ROI Cabmate uses electronic height control instead of a standard mechanical valve. Mechanical valves fill and exhaust air from the springs every time the valve mechanism moves out of its dead band. The ROI Cabmate addresses this challenge by employing electronic height control instead of a standard mechanical valve. The system will monitor changes in the height of the cab and will only fill or exhaust air when there has been a change in cab load cab, providing a quieter and more efficient operation that is more suitable for ZEVs.

Conclusion

The trucking industry is entering a new era, driven by rapid technological advancements and a pressing need to address the driver's health and safety risks associated with both long and short-term exposure to whole-body vibration (WBV). Central to this evolution is the emergence of semi-active suspension technology, a powerful tool that can significantly elevate the driving experience. By reducing the exposure to WBV, we can enhance the driver-experience, reduce health risks associated with driving, while improving operating efficiency and sustainability for fleets.

While semi-active suspensions are a relatively new addition to the industry, their potential benefits are already clear. From reducing vibrations that can cause driver discomfort and fatigue, to enhancing the longevity of capital equipment, the case for adopting this technology is strong. These benefits, combined with straightforward installation and maintenance processes, make semi-active suspensions an attractive proposition for fleet operators.

Semi-active cab suspensions, like the Link ROI Cabmate, offer a powerful solution to some of the most pressing challenges facing the fleet industry today. By investing in this advanced technology, fleet operators can significantly enhance the driving experience, improve their sustainability profile, and potentially reduce costs in the long run.

Blog Author

Eli DeGroff

Product Manager - Road Optimized Innovations