6 Ways Link Is Helping to Increase Fuel Efficiency

Drivers, Fleet Managers, and Business Owners feel the strain of rising fuel prices that only seem to keep going up. Luckily, even as these prices trend upwards, there are actions drivers and fleets can take to increase their fuel efficiency in today’s market. Many commercial vehicle industry best practices should be adopted such as educating drivers on good driving habits and watching speed. In these times of high inflation and operating costs, it is important for fleets and drivers to think beyond the standard practices and consider unconventional ways to improve fuel economy to offset rising costs.

Link Mfg’s products are designed to both improve the lives of drivers while also helping drivers and fleets win the battle against the rising costs. As a supplier of components ranging from suspensions for the cab and chassis and auxiliary suspensions, height control valves, and specialty products, Link Mfg has products and the customer service knowledge to help drivers and fleets get the most out of their equipment.

1. Reducing Compressor Run Time

Unnecessary air pressure consumption from braking and general suspension movements can increase compressor run time. The compressor adds load to the engine and can burn thousands of dollars’ worth of fuel every year. SmartValve® by Link reduces the rear suspension’s air consumption, requiring less runtime from the compressor. SmartValve has shown to reduce compressor run-time by almost 90% with the use of electronic height filtering; SmartValve knows when to use air for leveling, and not for responding to noise such as braking, acceleration, and going over bumps.

The ROI Cabmate® cab suspension similarly filters out unnecessary air consumption at the cab suspension. The electronics react in real time to road conditions and wind shear, reducing unnecessary air movement in and out of the airbags while also increasing the vehicle’s stability. As an added benefit reducing vibration from the roads could result in reduced wear and tear on vehicle components, meaning components last longer before replacement.

2. Advanced Aerodynamic Configurations

Technology that allows a vehicle to lower closer to the ground to improve aerodynamics has been around for a long time in high performance automotive cars. This technology was recently demonstrated on Freightliner’s Supertruck-II. The electronic controls of SmartValve make it possible for Dynamic Ride Height to work. Dynamic Ride Height decreases drag by automatically lowering the suspension while the vehicle is traveling at highway speed. This system does not require any input from the driver to activate and is available as an option on Freightliner’s Cascadia.

3. Consider Alternative Axle Configurations

While most trucks in North America run in a 6x4 configuration, it’s been found that trucks that run in a 6x2 configuration have increased fuel efficiency and tire life. Volvo and Mack are at the forefront of this movement, working with Link to provide a 6x2 pusher axle that automatically senses weight differentiation. For lighter loads below 16,000 lbs. the lift axle automatically raises up to 4 inches, reducing rolling resistance and wear on the tires. As an added benefit the lift axle comes with significant vehicle weight savings compared to a driven axle, directly impacting the vehicle’s fuel economy.

4. Preventative Maintenance Matters

Routine preventative maintenance is important to maintaining a vehicle’s longevity and fuel efficiency. Regular oil changes and clean air filters are among the common and basic maintenance items. With every routine maintenance, you should consider inspections of all height control valves. A height control valve that leaks or does not maintain proper ride height could be directly impacting the tractor’s fuel economy. Leaking height control valves consume air pressure requiring the engine driven compressor to run more frequently – increasing load on the engine and accelerating the wear of components. A truck that is not set to the manufacturer’s specified ride height is more likely to have driveline vibration and not operate at peak efficiency. Link’s All-Makes Mechanical Height Control Valves are designed to easily mount with any application on the road. Link’s mechanical valves use a plunger style design that eliminates potential air leakage. With over 40 years of experience, this design has proven to outperform other valves in the industry.

5. Load Weight Distribution

Properly loading and balancing a truck and trailer is almost a science in the trucking industry. There are a lot of tools that help drivers understand how much they are hauling and how to adjust the truck and trailer. Link’s Easy Slider® Sliding Kingpin system allows drivers to adjust the trailer kingpin position on a fully loaded, connected trailer without having to disconnect the kingpin from the fifth wheel. By varying the overall length of the tractor/trailer unit, the axle weight distribution can be optimized for load configurations and road conditions, thereby maximizing traction, and improving fuel efficiency.

6. Tire Pressure at a Glance

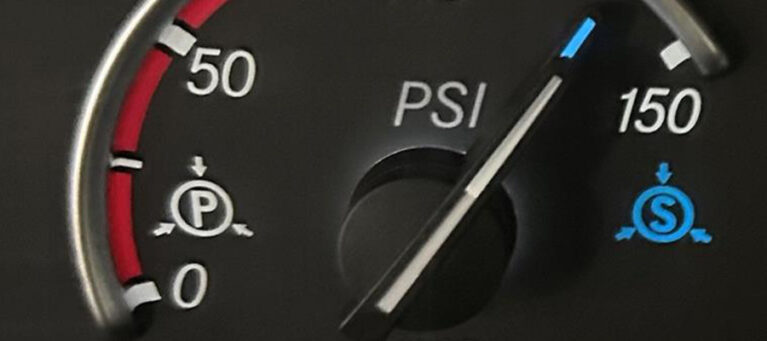

A truck’s tires are among the easiest places to pay attention to in order to ensure maximum fuel efficiency. Properly inflated tires reduce drag and uneven wearing, both of which contribute to lowered milage. With just a 5% difference in PSI between dual tires on a hub, the tire with the lower pressure will drag 13 feet every mile. This drag impacts both tire life and fuel economy. Tire pressure monitoring systems are one way to help drivers keep an eye on tire pressure and know when their tires need a bit more air.

Link’s Cat’s Eye® Tire Pressure Monitoring System is a sealed gauge which installs on the outer dual tire, allowing drivers to quickly and easily see when air pressure needs attention, greatly reducing the risk of a blowout while extending tire life. The user-friendly gauge allows air to transfer from one tire to the other, equalizing the pressure in both tires. An internal check valve provides added safety by preventing both tires from going flat in the event of a leak, a blow out, or if one of the pressure hoses is damaged.

While fluctuating fuel prices may be daunting, there are steps any driver and fleet manager can take to maximize fuel efficiency. From driver education to high tech vehicle components, small and large steps both can be taken to increase fuel efficiency. Link strives to continuously improve the lives and efficiency of drivers and fleets by offering solutions to reduce compressor run time, aid in maintaining proper tire pressure, and reduce unnecessary air movement through the cab suspension’s air bags. If you have any questions about Link’s products, please let us know. Our team is happy to answer questions and help you find a dealer near you.

Blog Author

Kirt Weaver

North American Sales Manager – Fleets